TBM Roof Collapse Repaired by Polyurethane Grouting |

While driving the Hanlon Water Feedermain tunnel through a residential district of Mississauga, Ontario, an unexpected vertical fault was intersected that resulted in a sudden roof collapse. The tunnel was being driven through shale with an open 3 m diameter TBM using rockbolts, straps and welded wire screen for behind-the-machine roof support. The vertical fault zone was oriented at 45° to the tunnel axis and was initially intersected by the right side of the TBM Cutterhead. As the left side of the cutterhead went through the fault, the roof collapsed, this stopping the TBM. The 3m diameter TBM was then trapped beneath the fault zone that slowly collapsed to eventually create a void measuring 3m x 3m x 3m. Water seepage was minor, but the shale roof continued to collapse slowly and undermine city streets approximately 10m overhead. After an unsuccessful search for suitable materials to fill the void directly over the TBM, the contractor called Multiurethanes - a Mississauga-based company specializing in the supply of grouting materials, equipment and engineering support services for mine and tunnel grouting operations. Various alternatives were discussed, including the use of conventional cement grouts, light-weight cement foams, two-component insulation-type polyurethanes. In the end, all of these materials were rejected due to time constraints and the practical difficulties associated with applying such materials in a tunnel on top of a TBM. The contractor's major concern was to avoid grouting his TBM into place. "It wIll be expensive", said Chris McNally of C&M McNally, "but I know that working with Multiurethanes will help us to get the job done fast." This statement was made following our site visit at 10 PM in the evening. The first delivery of the selected grouting product, a high-yield, water-activated, semi-rigid polyurethane foam, was made before midnight. By early morning of the following day, rental grout equipment and technical specialists were on site to work with McNally personnel. By mid-afternoon, the job was done and cleanup was underway to resume TBM operations. Prior to the grouting operations, McNally crews had placed welded wire screen over the TBM and a layer of broken shale had accumulated to a depth of approximately 0.5m. Several open plastic pipes with a diameter of 40mm were inserted through the broken shale and extended up to the top of the tunnel. Fiberglass insulation was used in places to prevent fine muck from spilling through the wire mesh screen. A grout mixing station and grout pumps were located at the tail end of the TBM where locomotives and flatcars could deliver grouting materials. Two grout pumps were used for this project-a large 20 litre per minute compressed-air pump for polyurethane and a small 1.5 litre per minute electric pump for water. These pumps delivered the grouting materials using high pressure hoses passing through the TBM machinery and control station. A manually-operated, two-valve grout manifold was positioned in the space between the TBM and the Cutterhead, directly beneath the void and within line-of-sight to both sides of the TBM. An open discharge hose ran from the grout manifold up through the 40mm plastic pipes and into the top of the void. Polyurethane grout was pumped into the void at a steady rate based upon the capability of the grout pumping crew to pre-mix polyurethane resin with accelerator. The maximum accelerator dose rate was used to achieve a very fast product curing time-less than 30 seconds. Water was added into the polyurethane stream by manually operating the water supply valve on the grout manifold to maintain an optimum 50:1 resin-to-water ratio. The grouting system allowed to water-activated reaction to commence within the open discharge hose so that the polyurethane was foaming as it cascaded out of the hose at the top of the void and was curing as it landed on the muck pile. As can be seen in the accompanying photos, the overlying muck was encapsulated by polyurethane foam which held in place, allowing TBM operations to resume, following which a permanent roof support system was installed. |

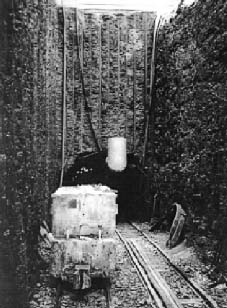

Tunnel portal situated in shaft excavation showing typical ground conditions in shale beds underlying Mississauga

|

|

A 40mm plastic pipe was inserted through the broken muck pile and extended up to the top of the void; view along the right side of the front end of the TBM beneath the void shows polyurethane foam extruded through the broken muck on top of the TBM

|

||

Grouting specialist shown with tunnelling crew alongside TBM with roof support installed in competent ground

|

||

Upon completion of polyurethane grouting operations and removal of fiberglass insulation used to hold fine muck, polyurethane foam can be seen encapsulating broken shale

Contributed by: Peter White, P. Eng., General Manager www.multiurethanes.com |

||