New In GeophysicsBy France Goupil |

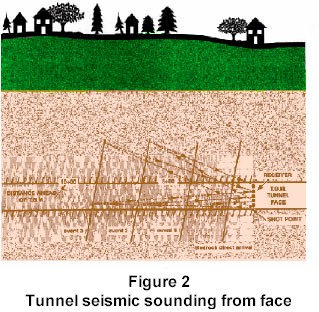

The typical approach of using geophysics in the exploration stage of tunnel planning is well established as far as seismic refraction and geo-electrical surveys are concerned. These techniques have been used in many projects, for example, the tunnel under the English Channel (La Manche), to locate geological changes, faults, and fracture zones in the bedrock. Figure No. 1 shows the typical results from a seismic refraction survey for a tunnel alignment.

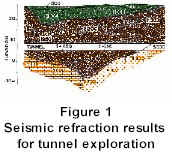

This new technology is mostly based upon faster acquisition systems and the capability of processing software imaging, 2D or 3D, the area or the volume, respectively, traversed by the survey. The interpretation of the results is derived by solving multi-path coverage of seismic energy traveltimes and performing an inversion process on the data. This is done to obtain an image of the seismic-velocity distribution corresponding to the traveltime measurements and presented as tomographic results. In tunnelling, tomagraphy is mostly used in areas where concrete and chemical grouting have to be controlled. The geophysical measurement are made before and after injection to determine changes in velocity corresponding to the success (or failure) of the injection process. This technology is quite interesting if it can be constructed in a 3D format. The technology is nondestructive, non-intrusive, rapid, and very reliable. The grouting success can be evaluated by an analysis of any remaining voids by using the seismic velocities measured before and after the grouting operation and comparing the processed energy-wave distribution. As some major project quality assurance requires proof of the completeness of the grouting program, such technology useful in many geological settings. As an exploration tool, tomography can be used between boreholes. In the case of a tunnelling exploration project, the boreholes have to be placed too closely together to make this technology a suitable and economic exploration tool. Tomography is more useful in evaluating specific geological situations, controlling grouting, or evaluating rock stability for short or long-term construction projects. As applied to tunnel construction, new geophysical applications have been conducted during the last few years. These investigations are generally used for the visualization of the geology in advance of the boring machine or conventional drilling and blasting, for the prediction of collapse due to the presence of voids, the position of faults, or other unusual geological features. As in tomography, other geophysical techniques can be used, such as georadar, to identify the electrical conductivity of in-situ rock. Changes in conductivity are frequently associated with water-filled bedrock fractures. As discussed previously, new approaches for tunnelling investigations during construction most often use the properties of georadar and seismic wave propagation. The capability of processing the data has been derived mostly from the oil and gas industry. Georadar surveys used during tunnel construction are very similar to those used for ground surface surveys. Georadar can be used on the roof or walls of a tunnel to locate fractures, establish the optimal lengths of rock bolts, and qualitative control of grouting. Georadar results can have particular interpretational problems in certain mediums and is also limited in distance of penetration. A more advantageous technique was developed utilizing seismic energy waves. This technique is closely related to traditional seismic refraction surveys and it has the same advantage of measuring seismic velocities, which are directly related to the mechanical properties of the investigated materials. Adapting seismic techniques from the oil and gas industry has required

scale adjustments in the measuring instruments. Only sophisticated seismic equipment can

take the accurate readings and, in part, may depend on the features that are the

objectives of the survey. Recently, data were acquired in a tunnel in Montana, USA to

locate fault zones in advance of a boring machine. The results shown in Figure No. 2

display the pattern of reflections at the tunnel recording face 150 m from the fault. The

seismic results were later confirmed with horizontal boreholes. One of the advantages of these techniques is that they generally do not require large pieces of equipment, extensive setup, nor many personnel. The data can be rapidly processed onsite if nearrealtime results are required prior to advancing the excavation. To complete this brief review or update of geophysical applications to tunnelling, I would like to present a technology that is most applicable to the rehabilitation of tunnels rather than for exploration. As more and more infrastructures, such as tunnels, piers, and underground foundations will need to be repaired in the coming years, a new field of geophysical surveys, microseismic methods, is developing to guide and control more efficiently these future repairs. Microseismic methods are being used on concrete slabs to map the weak areas by an analysis of seismic waves. Complex interpretation can be made on the waves to solve different geotechnical problems, and the most common interpretation is done based on longitudinal and shear-wave propagation times to locate weak areas. McGill University, located in Montréal, is developing with Geophysics GPR International Inc. a complex program to establish the optimal type of survey and the amount of coverage to assure a certain percentage of material changes to solve a specific problem. These numbers and techniques will be different at each site depending on the required accuracy and on the investigated structure. Micro-seismic techniques can be used to verify the integrity of concrete within a tunnel shaft. Generally, conditions such as fractures, voids and weak zones in a material can be iden tified without the need of boreholes. Micro-seismics is a much more powerful tool than the usual impactecho or ultrasonic testing methods. This is because the data can be processed using the same interpretational techniques used in seismic refraction, thus having fewer unknowns in the interpretation due to the extensive usage of these techniques applied to civil engineering. Even now these technologies are continually improving in mode of acquisition and in the processing of resultant data. We can also expect improved types of measurements, which means new types of wave generation, processing, and interpretation to reduce the risk in tunnel planning and construction. Before planning a project, a qualified geophysicist experienced in the above-mentioned techniques should be consulted. In fact, the overall technology is changing so rapidly than if one wanted to follow the current geophysical research, it would be necessary to consult, in the Journal of Geophysical Research alone, more than 40,000 pages of annually published articles. It is well known that the learning process will always keep a non-expert behind the new technology. The qualified geophysicist shall find the right solution at the lowest cost. |

During the past few years, a number of technologies

have been adapted from the medical sector and from the oil and gas industries to

geophysical exploration for civil engineering, such as tunnel and foundation projects.

Based upon the physical properties of sound and electromagnetic energy waves travelling

through a medium, in our case it could be concrete, rock or soil, it is possible to image

the subsurface conditions. The characteristics of the energy waves will be influenced by

the geology and by features such as voids, fault zones, and other anomalies. These

measured properties include the velocity of the energy, the amplitude or the quality

factor, electric conductivity of the material, and the variation of the measured

properties, and are used as the basis for geophysical interpretation of the investigated

intervals.

During the past few years, a number of technologies

have been adapted from the medical sector and from the oil and gas industries to

geophysical exploration for civil engineering, such as tunnel and foundation projects.

Based upon the physical properties of sound and electromagnetic energy waves travelling

through a medium, in our case it could be concrete, rock or soil, it is possible to image

the subsurface conditions. The characteristics of the energy waves will be influenced by

the geology and by features such as voids, fault zones, and other anomalies. These

measured properties include the velocity of the energy, the amplitude or the quality

factor, electric conductivity of the material, and the variation of the measured

properties, and are used as the basis for geophysical interpretation of the investigated

intervals.