Now just $395

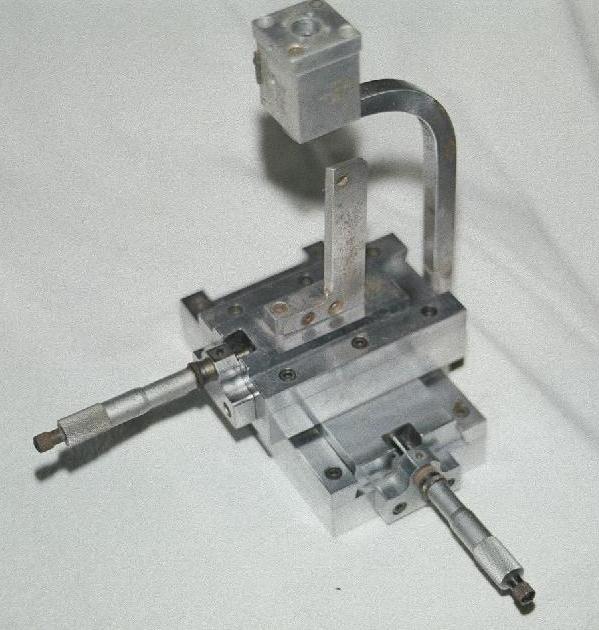

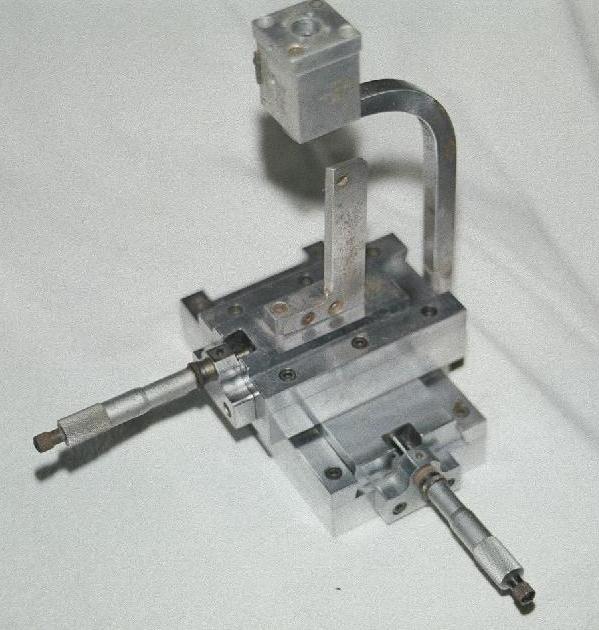

A Superior Foucault/Caustic Tester

CNC machined with the tightest tolerances for the utmost precision. German designed and made from 6061 aluminum. Note the slit is directly above the

knife edge yielding no astigmatism. Uses two 1/1000th of an inch micrometers and can measure 1/20 wave with the foucault test and up to 1/100 wave

with the caustic test. Now it is affordable to own the best equipment for your optical testing. Introductory price is $395 USD plus S&H.

Interested inquiries can be emailed to Send Email With Foucault Tester in the subject line. Payment can be made by

Paypal using the Paypal button.

Get your order in now for our next production run in the spring.

All funds secured with Paypal.

Regular price is $595.

web counter

Keywords: foucault tester knife edge tester knife-edge tester ronchi tester caustic tester ronchi caustic mirror making

telescope catadioptric newtonian gregory schmidt cassegrain parabola sphere testing apparatus dial indicator micrometer

slit radius of curvature focal length autocollimation polishing mirror maker pitch lap cerium oxide amateur telescope maker

zones test mask grinding grit micron powder wet grinding stand tool plate glass pyrex astro sitall astrositall sagitta abrasives

silicon carbide pitch squares optics testing equipment pinhole testing and correcting turned edge oblate spheroid ellipsoid

paraboloid hyperboloid figuring waves mirror correction making pitch squares shadows lens lense secondary primary effective

focal length shadow appearance inside focus outside focus zonal measurements light beam light source dog biscuit spider web

stroke length grinding stand concave convex mirror blanks turned down edge turned up edge shadow test spherical aberration

wavelength of light collimation baffle tubes maksutov gregorian meniscus reflecting refracting light rays coma astigmatism

curvature of field distortion mirror blanks mirror making kits razor blade upper curve lower curve paraboloidal curve centre

zone image shadow patterns cone of light correction curve measured curve hyperbolic edge eliptical edge ellipsoid oblate edge

central hill aspherized radius testing spherometer

Telescope Making

Telescope Making

Web Ring

Next |

Previous |

Random |

List Sites

Next 5 |

Previous 5 |

Join

Telescope Making

Telescope MakingWeb Ring |

|

Next |

Previous |

Random |

List Sites Next 5 | Previous 5 | Join |